That the Ghirarduzzi company constantly dedicates itself to researching new methods and technologies to obtain the best results in the field of materials recycling is no news now, and those who know it and follows his projects published in the News section of his website, you will certainly have noticed it.

But sometimes these innovations do not come as the result of latest generation technologies, but rather from applications of intuitions from the past, which perhaps have been lost over time, a little forgotten, a little “left in the attic to be covered in dust”.

Then one day, brushing up on your knowledge, you understand that it can make sense and then you start with research and experimentation.

This is the case of the vibrating separator that we are developing, with the aim of separating a hard material that bounces from a soft material that does not bounce, but which feels the vibrations induced by an artificial vibrating system.

Said like this, it might seem difficult to understand, but by giving an example of what could separate, everything becomes clearer.

In the recovery of metals, especially linked to the recycling of automotive components, waste materials containing copper cables can be found as residues from other processes strong> (of the wiring) still containing non-ferrous metals (stainless steel) in considerable quantities.

In order to recycle this product it would be necessary to grind it to reduce the size in order to detach the insulating plastic of the cables from the copper itself, but with the presence of hard and large pieces size like the stainless steel parts we mentioned, there is a risk of destroying the knife mill necessary for processing the copper cable, so very often large quantities of this material accumulate which potentially has a good market value, but you do not have the possibility of working it.

In this regard, this vibrating separator has the purpose of separating these parts of solid and hard metal from the copper cables, subsequently allowing all the processes necessary to recover the copper to be carried out.

And how is this operation possible? Well in reality the basic concept is quite simple, a little less is creating a machine that applies this concept to reality.

To make things simple to understand we can imagine that the hard and massive material could be represented as a bouncing ball, like those of children, while the soft material that does not bounce could be represented as many pieces of electrical wire strong> like that of electricians.

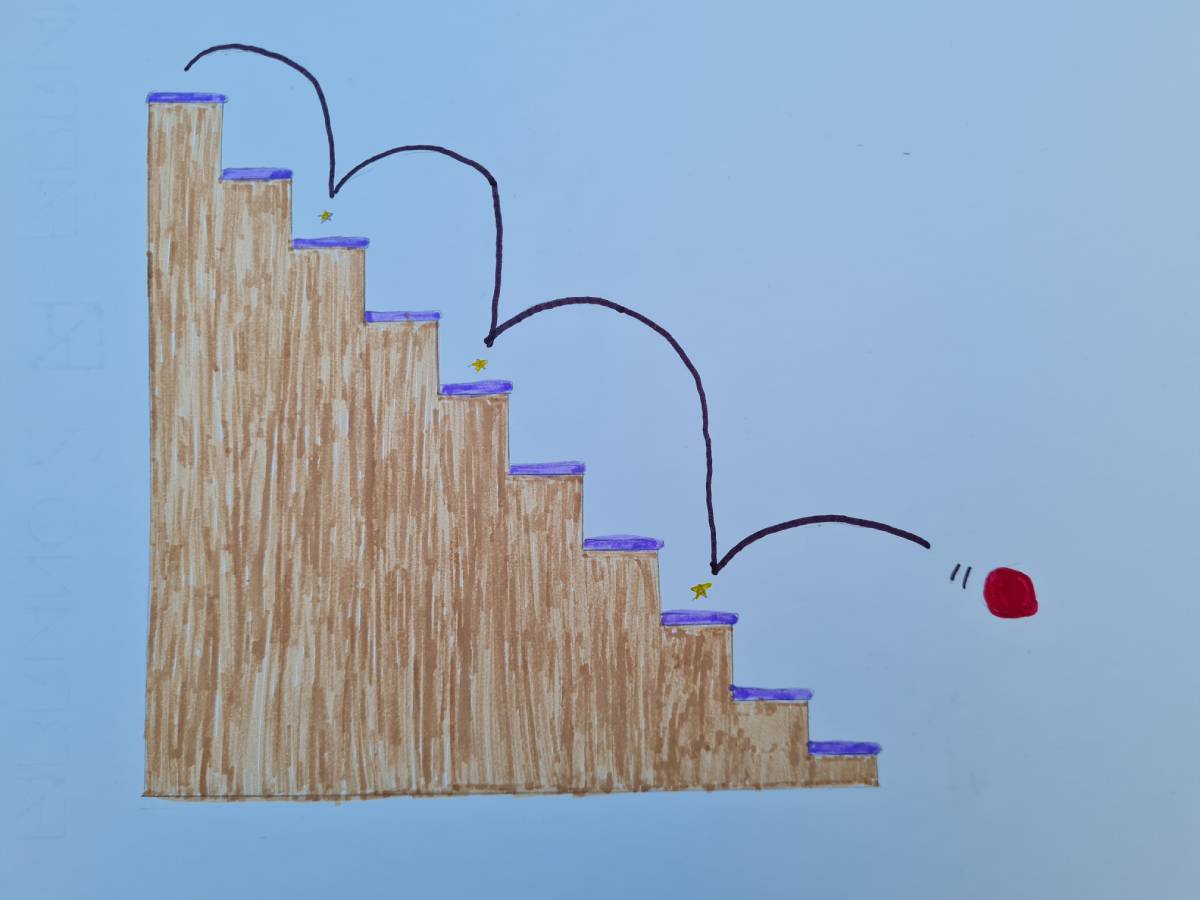

Now let’s imagine we are on a flight of stairs, and a ball falls from our pockets, it will bounce from one step to another and will stop only after having gone down all the stairs, on the contrary the pieces of electrician’s wire will fall on the first step or on the second and they will remain where they are.

This is more or less the concept. Obviously all this must be adapted to industrial criteria, hourly production and a thousand other problems that make this thing much more difficult and distant from what the pure basic concept is.

Clearly this project is great news for the Ghirarduzzi company and for all those materials in which this problem is present, in this regard we have built a machine whose name is VS 100 which we are testing with very similar materials to those described, obtaining more than good results from the first tests.

Tests on this new separator are continuing to understand any changes and/or adjustments to be made to the machine in order to obtain the best possible result.

Unfortunately we cannot show any image of the machine, but only a small frame of the separated materials. We hope to finish the tests in autumn and be able to start with the production of the first separators during the first half of 2024.